My name is [Your Name], and I am a specialist in reliability engineering, which is crucial for ensuring the performance, safety, and efficiency of technical systems. My expertise focuses on evaluating the performance of complex systems, particularly in critical sectors such as aerospace, transportation, energy, and industrial systems. Among the fundamental concepts in reliability engineering, availability is key, as it determines to what extent a system can deliver the expected service when required.

What is Availability?

Availability is a measure of a system’s ability to be operational and ready to perform its function at a given time, taking into account the downtime caused by failures and maintenance. Unlike reliability, which focuses on the absence of failures, and maintainability, which deals with the ease and speed of repairs, availability combines both aspects: it evaluates the system’s ability to function without failure (reliability) and to be restored quickly when a failure occurs (maintainability).

Availability: Is it Simply Reliability + Maintainability?

It would be incorrect to say that availability is simply the sum of reliability and maintainability, as these concepts are complementary but distinct. Availability depends on the interaction of these two factors but does not literally add them together.

- Reliability measures the probability that a system will operate without failure over a specified period.

- Maintainability measures the ease and speed with which a system can be repaired when a failure occurs.

Availability combines these two aspects: a reliable system may not experience many failures, but if it is difficult to repair, its availability could still be reduced. Conversely, a system with frequent failures but rapid repairs could have acceptable availability. This interplay between reliability and maintainability determines a system’s level of availability.

Different Types of Availability

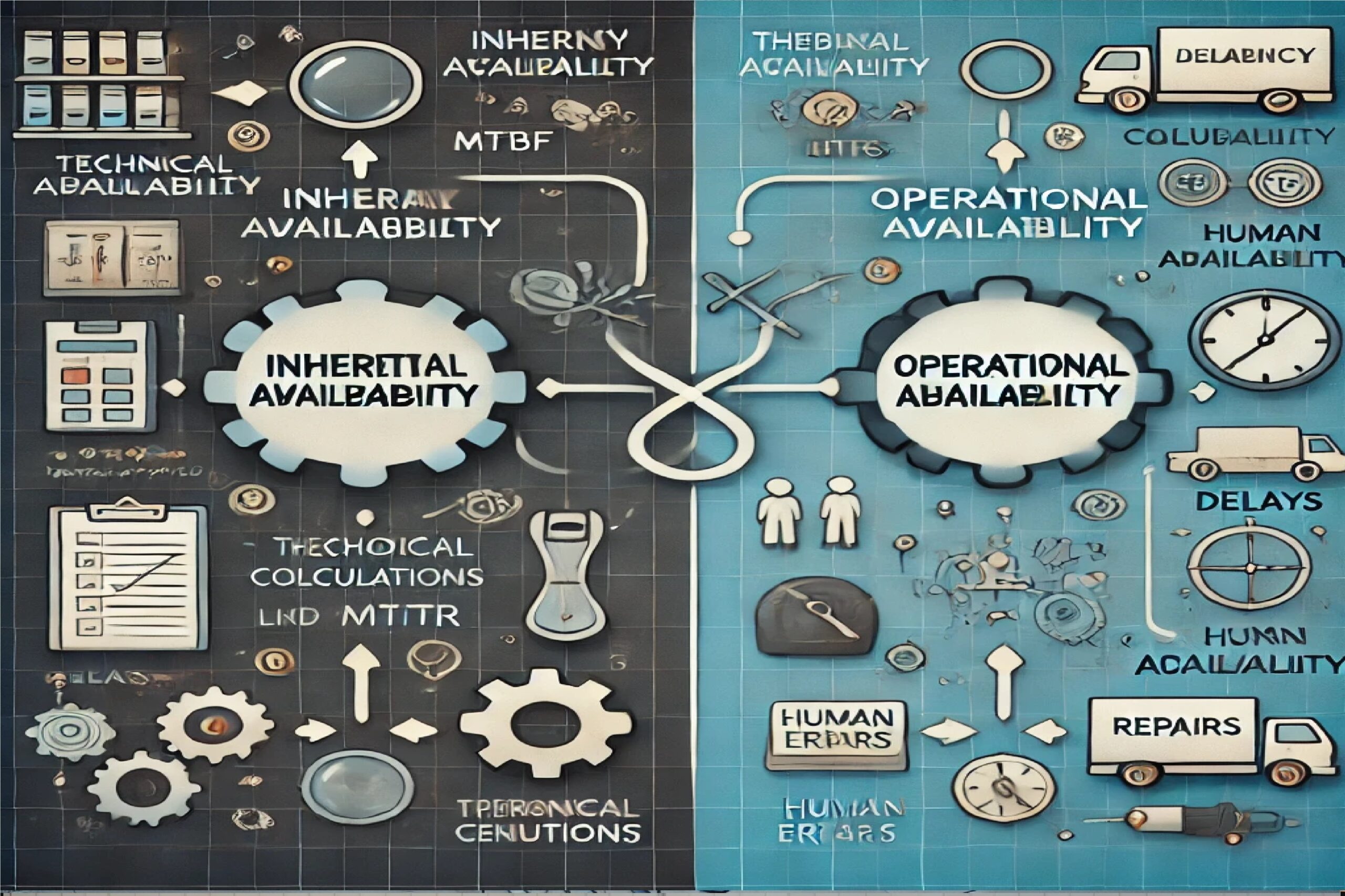

There are several types of availability depending on the context and calculation methods. The two main types are:

- Inherent Availability (or Predicted Availability):

- Inherent availability is an estimate of system availability before it is in operation, based on theoretical models and design data. It is calculated using the system’s reliability and maintainability specifications.

- This estimation uses probabilistic calculations, typically with parameters like MTBF (Mean Time Between Failures) and MTTR (Mean Time To Repair).

- Mathematical formula: Inherent Availability=MTBFMTBF+MTTR\text{Inherent Availability} = \frac{\text{MTBF}}{\text{MTBF} + \text{MTTR}}Inherent Availability=MTBF+MTTRMTBF This allows for evaluating theoretical availability based on the frequency of failures and the time needed to repair them.

- Operational Availability:

- Operational availability is based on real-world data collected during the system’s operation. It accounts for unforeseen events, real-world operational conditions, maintenance conditions, and the actual effectiveness of operations.

- Unlike inherent availability, operational availability reflects the real-world challenges, such as delays in obtaining spare parts or human error during maintenance.

- Similar formula: Operational Availability=Actual UptimeTotal Theoretical Availability Time\text{Operational Availability} = \frac{\text{Actual Uptime}}{\text{Total Theoretical Availability Time}}Operational Availability=Total Theoretical Availability TimeActual Uptime This formula takes into account the unpredictable factors that affect overall system performance.

Importance of the Two Types of Availability

- Inherent Availability:

- It is used in the design and planning phase of a project to ensure that the system will meet the expected performance requirements.

- It is crucial during the evaluation of technical solutions before production or installation begins, especially during bid evaluations and feasibility studies.

- Operational Availability:

- It is assessed after the system has been deployed and is in use. It helps validate theoretical performance and identify any gaps between theory and reality.

- This is a key indicator for operators and maintenance managers, as it reflects the actual performance of the system and allows for adjustments in maintenance plans to improve overall efficiency.

Calculating Availability: Key Inputs

To calculate availability, whether inherent or operational, several key data points are needed:

- MTBF (Mean Time Between Failures): Indicates the average time between failures.

- MTTR (Mean Time To Repair): Measures the average time for repairs, including diagnosis and time to obtain spare parts.

- Maintenance data: Includes the frequency of preventive and corrective maintenance activities.

- Real operational conditions: For operational availability, it’s essential to consider unforeseen factors (spare part delays, human errors, environmental conditions, etc.).

When to Use Each?

- Inherent Availability: Used in the early stages of the project, during design and planning, to ensure that the proposed system meets contractual requirements.

- Operational Availability: Used during and after the system’s deployment to adjust maintenance procedures and improve overall performance.

Availability is a critical indicator that reflects a system’s ability to perform its mission under real-world conditions. By distinguishing between inherent availability and operational availability, we can better understand and anticipate a system’s performance throughout its lifecycle. Effective management of both types of availability helps minimize downtime and ensure better operational continuity, which is essential in critical sectors such as aerospace, energy, and transportation.